Areas

Our Areas: Technology, Innovation and Excellence at the Service of Your Success!

> Robotics

The first ice cream machines relied solely on the operator's strength, which was replaced by electric motors over time. With them, the man began to make less effort, but the main operations were still performed by him.

In the preparation of ice cream, chocolates and other foods, there is a common step which is the beating of the ingredients, some at low temperature, others at high, some gently, others vigorously, etc. Breads, sweets and pastas generally follow the same steps. To "automatically" execute this first step, the equipment was equipped with motorized mechanical systems to replace the "arm" of the operator.

With industrialization, the food preparation phase ceased to be the focus of the process. Other operations were necessary to meet demand and then self-controlled equipment was needed to avoid operational errors and excess labor. Food began to be dosed into suitable containers, packaged and distributed. Artisanal ice creams and chocolates, although they still require the skill of a specialized operator, have incorporated more sophisticated processes such as pasteurization and tempering, which require strict control by more sophisticated automated systems.

With the growth of digital technology, precision electromechanical actuators have emerged, which have greatly facilitated the automation of various types of equipment, starting with metalworking machines. Pneumatic actuators have also contributed significantly to the design of the first robots.

The most recent phase of this evolution, still within the growth of digital technology, occurred with the emergence of so-called "artificial intelligence", which uses computer codes to literally "think" about what action to take in the face of a series of variables. This is how a game of chess works with a computer. The human player makes a move and waits for the computer to analyze all possible alternatives for its next move, choosing the best one among several criteria pre-established in the program code.

Industrial equipment for the production of ice creams, popsicles and chocolates already uses artificial intelligence, albeit in a modest way.

Finamac™, in partnership with universities and specialized companies, has been developing a robotics laboratory exclusively to research new forms of intelligent automation of the machines it produces. See one of the results below:

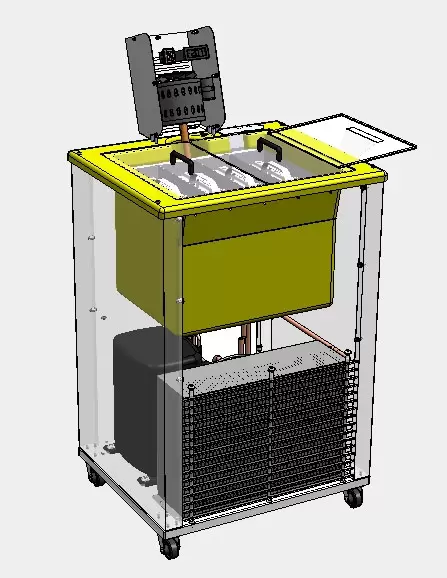

Equipment for packaging ice cream in the shape of cones, cups and pots. Electromechanical technology from the 1970s:

> Food

Since 1954, Finamac™ has been involved in the ice cream and food market on a daily basis. It operated ice cream shops and food stores for many years before starting to manufacture equipment.

Its founder, as a boy, even suffered facial paralysis caused by thermal shock from eating so many popsicles on a very hot day. He was cured with 6 months of physical therapy and electric shocks to the face, but he continued to frantically savor all the products made in the ice cream shop. This same boy, as an adult, took the initiative to start manufacturing equipment industrially in 1989, founding Finamac™ in Brazil.

The passion for ice cream, chocolates and food in general has never faded. Only a team that knows and sees the final product with a sparkle in their eyes can design equipment that generates food with greater flavor and quality.

Finamac™ has always maintained a food-focused area, especially because it is an industry that began as an ice cream shop. Here, several courses are taught and all equipment is tested with a huge variety of products.

Over the years, we have been given the opportunity to supply equipment from small producers to large ice cream companies, such as Unilever and Nestlè. This has given us a deeper understanding of the concept of quality in the final product.

Ice popsicles sold in low-income neighborhoods, although seen as examples of low quality, have countless merits if we take into account the purpose of the food produced: low cost, natural ingredients, refreshing, fun. On the other hand, ice creams with more elaborate ingredients, although seen as examples of high quality, have demerits if we take into account the need to use some chemical components.

Likewise, the regionality of the food is a very important aspect. An Italian ice cream, for example, made with beet sugar, differs greatly from an ice cream made with cane sugar, typically Brazilian, especially in the performance of the machine that produces them.

Combining the taste and raw material resources of each people around the world with the performance and ease of operation of a given piece of equipment is not an easy task and requires a lot of research and innovation. For this reason, a machine to produce Italian ice cream needs to have significantly more power than a machine to produce Brazilian ice cream. But this does not mean that the ice cream or the machine from one country or another is of greater or lesser quality.

We attribute the quality of a food to factors that are more comprehensive than simply the sophistication of its recipe or the process by which it is manufactured. A simple homemade dessert can be of excellent quality if the family asks for more, this is the first aspect. Second, if we can find out how much potential customers would pay to have this dessert in their homes, then external factors that also make up the quality begin to come into play.

A successful food needs to meet, in addition to the healthy food aspects themselves, the entire consumption chain, providing palatable and differentiated commercial results.

> Thermal

The first ice cream machines used snow and salt around a metal container where the ingredients were mixed. With the advent of industrial refrigeration, ice cream production underwent great progress, as did the preservation of many other foods.

On the other hand, heating food has long been a process of using fire. Heating combined with cooling gave rise to more elaborate processes such as pasteurizing milk and tempering chocolate.

Thermal processes are currently part of the preparation of most foods, but they play a special role in the making of ice cream. The most intriguing aspect of thermal phenomena is that they cannot be seen, unlike mechanical phenomena. We know that a refrigerator works with a gas compressor, but we cannot see what is happening inside the circuit.

In times when global energy is gaining tremendous importance, heat generation is beginning to be seen in a much more valuable way. Considering that the world we live in is heated by the sun and that without it we would freeze, we understand that cold is only the absence of heat and that what actually exists is heat.

Adding heat to a food means heating it and removing heat means cooling it. This is what we do with ice cream when it is being churned and frozen. We remove heat from it and release this heat to the outside environment, just as an air conditioning unit removes heat from a room and releases it to the outside.

The study of thermal processes is a fundamental step in the research of new processes for producing ice cream, chocolate and similar products. Finamac™ has been developing its thermal analysis laboratory in order to increasingly understand the phenomena involved and to seek new alternatives for transporting energy between food and the environment.

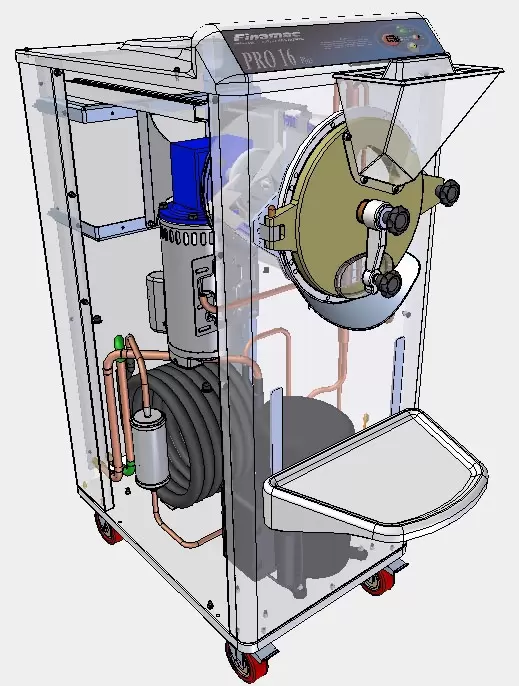

The result of this can be seen in the first heat pump pasteurizer, patented and developed by the Finamac™ research team, below:

> Technological

This equipment is a valuable example of energy efficiency, since the same heat exchange system that generates heat to heat the ice cream mixture is also used to cool it, thus avoiding electrical resistance or gas (fire) for the heating process, which is much more expensive and aggressive.

> Design

With the industrial revolution, the name "machine" became a status symbol, and the more crude and robust its design, the better. For many years, the machine was more important than the product itself. Ice cream advertisements focused on machines, just as, by analogy, today the wood-fired oven is imperatively associated with pizza.

Although this focus is no longer seen as a selling point for ice cream, there is still a strong connection between ice cream and popsicles and the machines that produce them, mainly because you cannot produce a quality product without them, like you can produce homemade chocolate, for example.

Out of sight, out of mind

For many years, ice cream has occupied a prominent place in an ice cream shop and we know little about the machine that makes it. The reason for this is that, for hygiene and strategy (so as not to show the tools to the competitor), the equipment has always been hidden in ice cream shops in places where customers are not allowed access.

Since it is an impulse-sale product, which appeals to the heart and the palate, the simple display of ice cream in a freezer, especially those that are fully packaged, made this differentiation insufficient for the customer to prefer ice cream over chocolate, for example. This is how the concept of Italian gelato emerged, which displays ice cream in true fashion windows, without packaging, but the equipment remains hidden, out of sight, out of mind. McDonald's ice cream, or soft serve ice cream, was the first to display its equipment to customers, but unfortunately it still looks like a tank and does little to increase its appeal.

Contemporary design

Bringing machines to the forefront of the ice cream shop is a challenge that arose when our company was founded. Transforming industrial monsters into modern-looking equipment has always been part of our plans. From the beginning, we patented our industrial models, were copied, and today we set market trends. The first ice cream maker with a fiberglass tank (Fig. 1), replacing stainless steel, was made here.

Fig. 1. First ice cream maker with fiberglass tank.

Fig. 1. First ice cream maker with fiberglass tank.

We put an end to the problems of "electric shock" when touching the stainless steel tank, as well as the frozen surface that prevented anyone from putting their hand in the machine, in addition to problems with leaks, costs, etc. The first ice cream maker with a food-grade plastic lid also came from here (Fig. 2). |--|--|

|

Fig. 2. First ice cream maker with plastic lid. Because it is thermally insulating, it prevents the dripping of condensation water traditional to stainless steel lids, in addition to being able to have more elegant shapes and more attractive colors. The first machines with colored stainless steel cabinets also came from here. They are suitable for upscale environments, such as sophisticated coffee machines, usually with a navy blue or gold finish. Machines that weighed almost 500 kg now weigh just over 100 kg, after a complete change in the construction concept. Our Italian ice cream display cases, which can be seen in luxury shopping malls and ice cream parlors in upscale neighborhoods, are unique in Brazil and compete with the best European products, with the advantage of being tropicalized and with tempered and "fog-proof" glass. See fig. 3 below. |

|---|

|  Fig. 3. Thermally conductive glass used in ice cream display cases. Image rendered at the Finamac™ research center, from CAD files.

Fig. 3. Thermally conductive glass used in ice cream display cases. Image rendered at the Finamac™ research center, from CAD files.