Projects

Our customers around the world are using Finamac™ solutions to bring more innovation to the ice cream market

> All in One

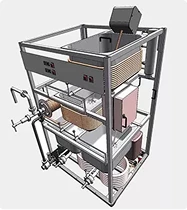

1) Complete equipment for pasteurizing and producing aerated ice cream.

1) Complete equipment for pasteurizing and producing aerated ice cream.

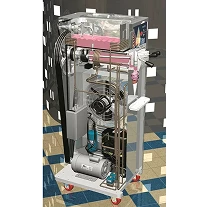

2) Equipment for the production of ice cream and popsicles, with mixing and pasteurization of ingredients.

2) Equipment for the production of ice cream and popsicles, with mixing and pasteurization of ingredients.

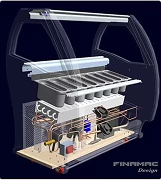

3) Preservation/Pasteurization and production of soft ice cream.

3) Preservation/Pasteurization and production of soft ice cream.

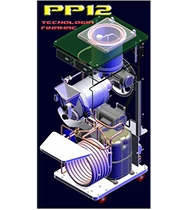

4) Displays for ice cream, popsicles, chocolates and sweets.

4) Displays for ice cream, popsicles, chocolates and sweets.

Displays for ice cream, popsicles, chocolates and sweets.

Displays for ice cream, popsicles, chocolates and sweets.

> Chocolate

1) First 100% Brazilian chocolate tempering machine.

1) First 100% Brazilian chocolate tempering machine.

2) Pasture Producer for the production of ice cream, creams and chocolates.

2) Pasture Producer for the production of ice cream, creams and chocolates.

> Popsicle

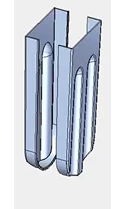

1. Molds

1. Molds

In traditional molds made of AISI 304 stainless steel, we investigated the difference in performance between sheet thicknesses of 0.5mm and 0.8mm, most commonly used by mold manufacturers in Brazil and abroad.

The theoretical modeling was based on using pure water inside the mold, taking into account only the total heat to be removed, without simulating the dynamic effects of exchange and phase change. Experiments under various conditions were conducted using only water inside the molds.

There is a 20% difference in freezing time between one thickness of stainless steel sheet and another. The 0.5 mm thickness proved to be faster and more applicable to molds for use in smaller capacity machines. The 0.8 mm thickness can only be used in more powerful refrigeration systems.

The 0.5 mm thickness proved to be inadequate for immersion baths in calcium chloride and sodium chloride, due to its low durability, while the 0.8 mm thickness can be used with sodium chloride only. For calcium chloride, 304 stainless steel is also inadequate.

2. Glycol immersion

We researched the use of non-toxic propylene glycol as a replacement for alcohol, commonly used as an intermediate fluid for freezing popsicles in small equipment.

From the previous research (item 1), we concluded that molds with a sheet thickness of 0.5 mm are only resistant to alcohol and should not be used with sodium or calcium chloride. However, alcohol has the major disadvantage of being flammable.

Non-toxic propylene glycol, mixed with water in the correct proportion, proved to be quite effective in freezing popsicles, without being flammable. Its major disadvantage is its cost.

From this study we obtained mainly theoretical and practical knowledge of the main characteristics that a fluid for this purpose needs to have. Basically, since it is a freezing system by agitating the fluid, in addition to the speed of its movement, its thermal conductivity as a function of its viscosity at each temperature is of vital importance for the final result.

3. Alcohol agitation system - patented

Traditional popsicle machines use a centrifugal pump to move the alcohol between the molds. Normally, the circulation direction goes from one side of the tank where the molds are located to the other, with the colder alcohol, coming out of the evaporator, coming into contact with the first molds, on one side, and losing temperature as it moves to the opposite side of the tank. This means that the popsicle molds never freeze evenly.

To solve this problem, we researched new ways of circulating the refrigerant fluid and came to the conclusion that the centrifugal pump is not a good solution because the flow rate drops significantly as its viscosity increases. Furthermore, as the alcohol evaporates during operation, the fluid becomes increasingly viscous and circulation becomes almost non-existent, greatly delaying the freezing of the popsicles.

The result of this research was the development of a propeller agitator that moves the alcohol from the bottom to the top, over all the molds at once, that is, instead of the alcohol moving from one side of the tank to the other, it moves from the bottom to the surface. The performance gain, even after most of the alcohol has evaporated, is impressive.

4. Evaporator with spheres - patented

As a complement to the previous research, we realized that the amount of alcohol contained in the tank could be reduced, which would further increase the efficiency of the agitation and the gains in thermal inertia. Since the evaporator was made with copper tubes immersed in the same tank as the molds, a considerable volume of alcohol was used just to cover the evaporator (commonly called a coil).

We studied an evaporator that occupied less than 1/3 of the volume of what was being used. To do this, we inserted aluminum spheres inside a small portion of the copper tube and the result of the new evaporator was fantastic.

5 Fiberglass tank - patented

5 Fiberglass tank - patented

Following the two previous studies, we noticed that the heat loss of the refrigerant fluid was not something to be ignored. The smaller the amount of fluid, the greater this effect was.

We then researched the alternatives for using alternative materials to stainless steel, normally used in tanks of this type.

The molded fiberglass solution proved to be the most suitable because it better accommodated the evaporator and the molds in prefabricated fittings. The biggest problem was finding the right material for

> Ice cream

1. The first electronic pasteurizer for ice cream and popsicle syrup - patented

The pasteurization of dairy products used to make ice cream and popsicles consists of heating the mixture to 85°C and cooling it abruptly to 4°C.

This was our first step towards process automation, which culminated in a dedicated electronic board that controlled all stages of pasteurization.

The machines on the market used only conventional electrical systems, with interlocked relays and electromechanical magnetic switches. The operation of a pasteurizer had the characteristic "switching" sound each time the electrical resistance was turned on to control the temperature reaching 85°C.

In addition to the on-board electronics, which anticipated actions for possible detected failures, the power drives began to be made by solid state relays, without any noise.

2. The first ice cream maker with temperature control - patented

2. The first ice cream maker with temperature control - patented

Ice cream making machines monitored the electric current of the motor that activated the beating of the ice cream. In this way, when it reached a certain value, which represented a certain consistency of the mass that was being beaten, the equipment would turn off.

Our research focused on a new system based on the temperature of the ice cream and no longer on the current of the electric motor. It is still a success today.

3. Control system for soft ice cream production - patented

Soft ice cream machines (Mc Donald's type) were operated entirely manually, which caused a series of problems. The most common of these was the operator forgetting to turn off the ice cream mixer and it jammed, making the next customer wait 15 minutes for the system to work again.

Most of the machines produced to date have not completely solved the problems involved in the production of soft ice cream, so they still use mixed manual/automatic systems. Mc Donald's employees, for example, only operate these machines after long and detailed training.

We researched for 4 years a system capable of understanding and acting when subjected to the most varied problems involved in the production of soft ice cream.

Our equipment is one of the only ones on the market that works uninterruptedly, acting correctly to correct possible failures, so that the operator does not notice what is happening. Furthermore, it was the first equipment on the market to have a system for counting the amount of ice cream produced and a password for operation.

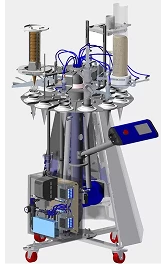

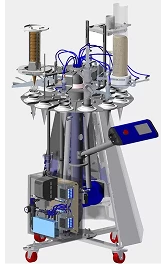

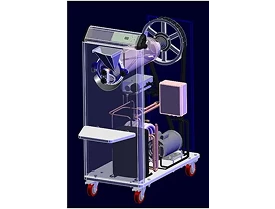

4. Ice cream cone, pot and cup filling machine - patented

4. Ice cream cone, pot and cup filling machine - patented

Considered the high point of automation developed at Finamac, this filling machine involved us for 3 years in research that culminated in an innumerable series of benefits. We first produced an electromechanical prototype to understand step by step how the ice cream filling process should work.

The second step was to research how the machines were made by the main manufacturers. The third and most important step was to highlight the points where we detected clear obsolescence, and from there we moved on to cutting-edge solutions. The result was a machine that weighs 1/3 the weight, is half the size and costs 40% less, and works intelligently and automatically. Any resemblance to a spaceship is purely coincidental...

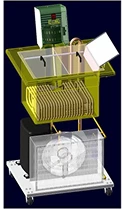

5. Control system for pasteurization plant

5. Control system for pasteurization plant

6. Control system for continuous ice cream production

6. Control system for continuous ice cream production

7. Monoblock structure - patented

7. Monoblock structure - patented